The field of industrial robotics has seen significant growth and development in recent years, with the introduction of new technologies and the emergence of innovative trends. In this blog post, we will explore some of the latest trends in industrial robotics that are driving innovation and transformation in 2023.

One of the key trends in industrial robotics is the adoption of Industrial Internet of Things (IIoT) technology.

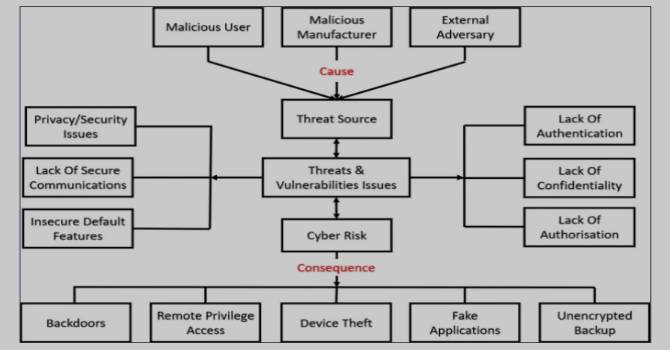

Industrial cybersecurity is a priority as industrial robots become more connected and intelligent.

Open automation architectures are another trend in industrial robotics that enable different types of robots and devices to communicate and collaborate with each other seamlessly. Open automation architectures are based on common standards and protocols that enable interoperability and modularity among various components. This allows manufacturers to customize their automation solutions according to their needs and preferences, as well as integrate new technologies easily. Open automation architectures.

It also facilitate innovation and creativity by allowing users to experiment with different combinations and configurations of robots and devices.

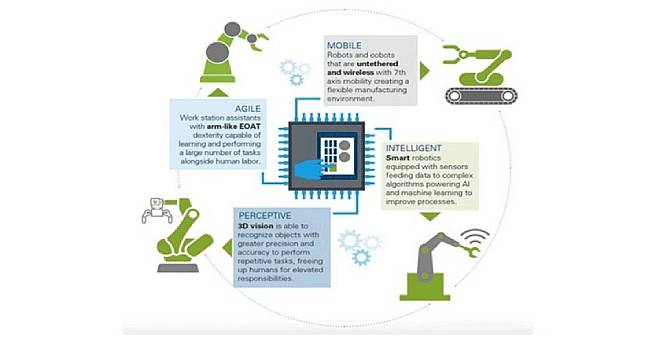

Collaborative robots (cobots) are becoming more prevalent in manufacturing settings, as they can work alongside human workers without the need for safety barriers. Cobots offer several benefits for manufacturers, such as reducing labor costs and shortages, improving productivity and quality, enhancing flexibility and agility, and increasing worker satisfaction and safety. Cobots can perform various tasks that are repetitive, tedious, or hazardous for humans, such as picking, placing, assembling, inspecting, or welding. Cobots can also learn from human feedback or demonstration through intuitive interfaces such as voice commands or gestures.

These are just a few examples of the latest trends in the field of industrial robotics. As technology continues to advance, we can expect to see even more exciting innovations in the years to come. The adoption of IIoT technology, big data analysis, industrial cybersecurity, open automation architectures, and collaborative robots are driving innovation and transformation in industrial robotics, enabling manufacturers to improve their competitiveness, efficiency, quality, safety, sustainability, profitability, customer satisfaction, employee engagement, social responsibility, environmental impact, and more. Industrial robotics is not only changing how things are made but also how people work, live, play, learn, create, connect, communicate, and contribute to society

C-70/1, 3rd Stage Peenya Industrial Area, Bangalore 560058, KA India