Robots are still evolving from their early days on the manufacturing floor, fearlessly tackling more difficult, nuanced tasks that earlier generations would have failed at. Working with robots to increase productivity and safety is now a reality, driven by economic incentives for cost savings and technological breakthroughs. Fully autonomous robots of all kinds are used in a variety of settings, yet bipedal, humanoid robots may still belong to science fiction.

Since the 1960s, robots have been used in the industrial setting to increase productivity and safety. Robots have long been a staple on factory floors, but it wasn't until the COVID-19 pandemic that they really began to take off in non-industrial contexts. What types of labour robots could perform and what humans should perform were both significantly impacted by the global health crisis.

The capabilities of robotics are simultaneously being pushed by technological breakthroughs. Robots are making impressive strides in dynamic displays, driven by strong machine learning and talented developers. As a result, businesses are observing a convergence of financial incentives and technology capability that is accelerating adoption.

In essence, robotic arms and other robots are trained to carry out straightforward or difficult tasks in order to recover valuable materials from waste. These robots can quickly sort recyclable materials using artificial intelligence, categorising them for efficient processing. This speeds up and improves the efficiency of recycling, producing recyclable materials of higher quality.

Robots can execute many of the same duties that would often need human workers, therefore they can assist save labour expenses in addition to sorting goods. Additionally, they may do it with greater accuracy and dependability, reducing any potential faults brought on by human error or exhaustion.

A robot consists of several parts that work together to perform a task. The main components of a robot are:

There are several types of robots, each designed for a specific task. The most common types of robots are:

Robot programming involves creating a sequence of instructions that the robot will follow to perform a task. There are several programming languages that are used to program robots, including:

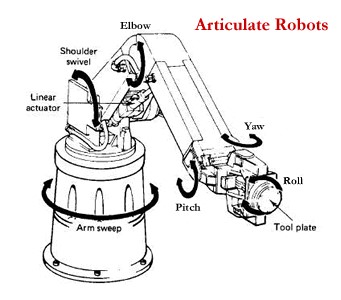

Articulated - This robot design features rotary joints and can range from simple two joint structures to 10 or more joints. The arm is connected to the base with a twisting joint. The links in the arm are connected by rotary joints. Each joint is called an axis and provides an additional degree of freedom, or range of motion. Industrial robots commonly have four or six axis.

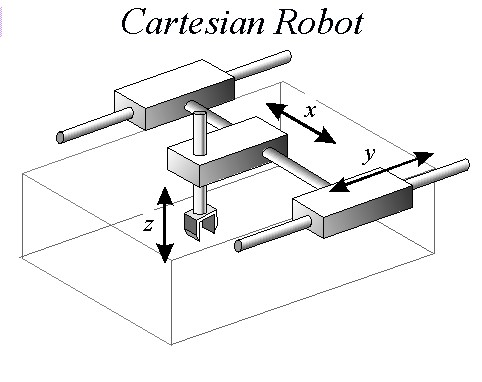

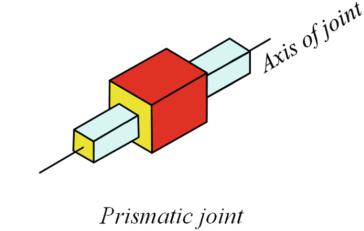

Cartesian - These are also called rectilinear or gantry robots. Cartesian robots have three linear joints that use the Cartesian coordinate system (X, Y, and Z). They also may have an attached wrist to allow for rotational movement. The three prismatic joints deliver a linear motion along the axis.

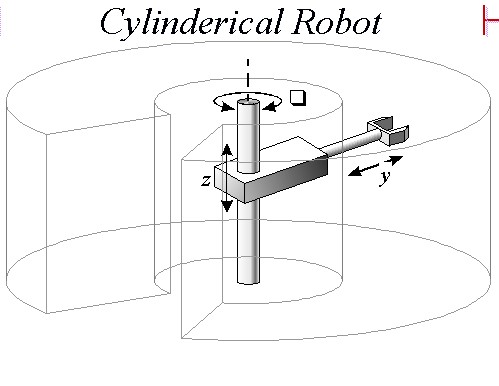

Cylindrical - The robot has at least one rotary joint at the base and at least one prismatic joint to connect the links. The rotary joint uses a rotational motion along the joint axis, while the prismatic joint moves in a linear motion. Cylindrical robots operate within a cylindrical-shaped work envelope.

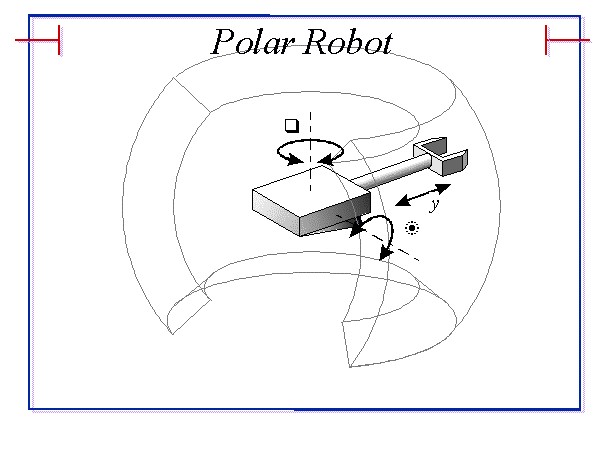

Polar - Also called spherical robots, in this configuration the arm is connected to the base with a twisting joint and a combination of two rotary joints and one linear joint. The axes form a polar coordinate system and create a spherical-shaped work envelope.

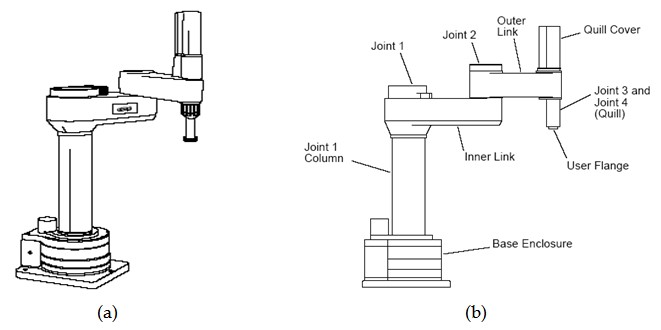

SCARA - Commonly used in assembly applications, this selectively compliant arm for robotic assembly is primarily cylindrical in design. It features two parallel joints that provide compliance in one selected plane.

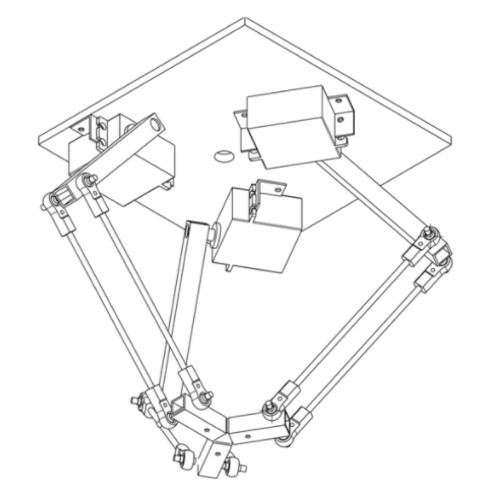

Delta - These spider-like robots are built from jointed parallelograms connected to a common base. The parallelograms move a single EOAT in a dome-shaped work area. Heavily used in the food, pharmaceutical, and electronic industries, this robot configuration is capable of delicate, precise movement.

Typical industrial robots are articulated and feature six axes of motion (6 degrees of freedom). This design allows maximum flexibility. Six-axis robots are ideal for:

Prismatic Joint: A prismatic joint is a one-degree-of-freedom kinematic pair that restricts the motion of two bodies to sliding along a common axis without rotation; for this reason, it is also known as a slider (as in the slider-crank linkage) or a sliding pair.

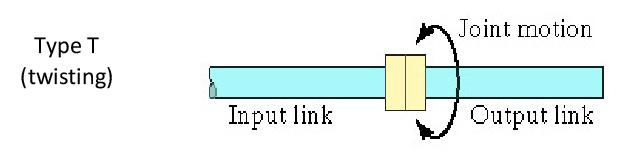

Twisting Joint: It is also known as V joint. This Joint makes Twisting motion among the output and input link. During this process, the output link axis will be vertical to the rotational axis. The output link rotates in relation to the input link.

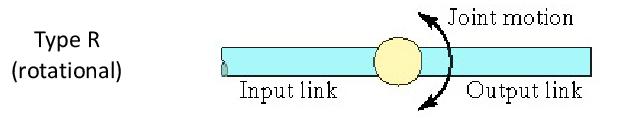

Rotational Joint: It is also known as R joint. This type will allow the joints to move in a rotary motion along the axis, which is vertical to the arm axes or perpendicular to the axes of the input and output links.

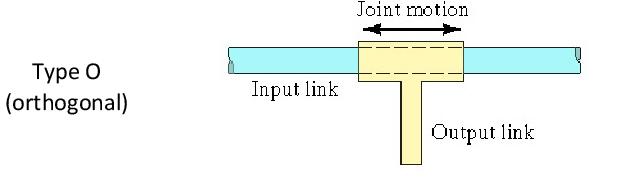

Orthogonal joints: It is somewhat similar to the linear joint but the input and output links are perpendicular to each other. The only difference is that the output and input links will be moving at right angles.

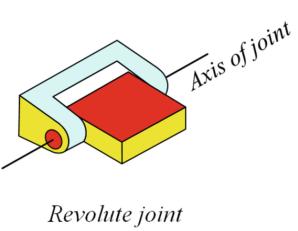

Revolving joint: Here, the output link axis is perpendicular to the rotational axis, and the input link is parallel to the rotational axes. As like twisting joint, the output link spins about the input link.

In robotics, mathematical equations are used to model the behavior of robots, plan their movements, and control their actions. Here is a brief explanation of some of the most common equations used in robotics:

1.Forward Kinematics Equations: Forward kinematics equations are used to determine the position and orientation of a robot's end effector based on the values of the joint angles. These equations vary depending on the specific robot and its configuration, but they generally involve matrix operations and trigonometric functions. The forward kinematics equations are essential for robot design and control, as they allow us to calculate the position of the robot's end effector without having to physically move the robot.

2.Inverse Kinematics Equations: Inverse kinematics equations are used to determine the joint angles required to position the robot's end effector at a desired location in space. These equations are generally more complex than forward kinematics equations, and they often require iterative methods to solve. The inverse kinematics equations are essential for robot motion planning and control, as they allow us to specify the desired location of the robot's end effector and calculate the joint angles required to reach that location.

3.Robot Dynamics Equations: Robot dynamics equations are used to model the motion of a robot and its interaction with the environment. These equations consider factors such as gravity, friction, and the forces and torques generated by the robot's actuators. The robot dynamics equations are essential for robot control and motion planning, as they allow us to predict how the robot will behave in different environments and under different conditions.

4.Path Planning Equations: Path planning equations are used to determine the optimal path for a robot to follow in order to reach a desired location in space. These equations consider factors such as obstacles in the environment and the robot's capabilities and limitations. The path planning equations are essential for robot motion planning, as they allow us to find the most efficient and safe path for the robot to follow.

5.Control Equations: Control equations are used to control the movement of a robot based on feedback from its sensors. These equations involve the use of feedback control systems, such as proportional-integral-derivative (PID) controllers, to adjust the robot's movements and ensure that it reaches its target location. The control equations are essential for robot control, as they allow us to adjust the robot's movements in real-time based on its environment and the desired outcome.

Understanding these mathematical equations and how to use them is essential for anyone interested in working in the field of robotics.

C-70/1, 3rd Stage Peenya Industrial Area, Bangalore 560058, KA India