Your Machine & Automation Partner, High Quality Manufacturing

UVASKA-ETS with 15 years of experience in the industry, we have established ourselves as a trusted and reliable partner for any industrial solution needs.

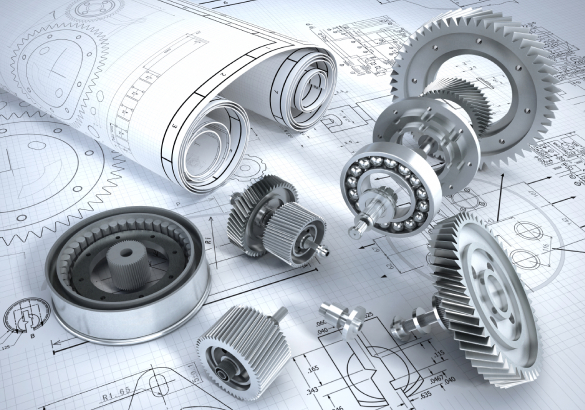

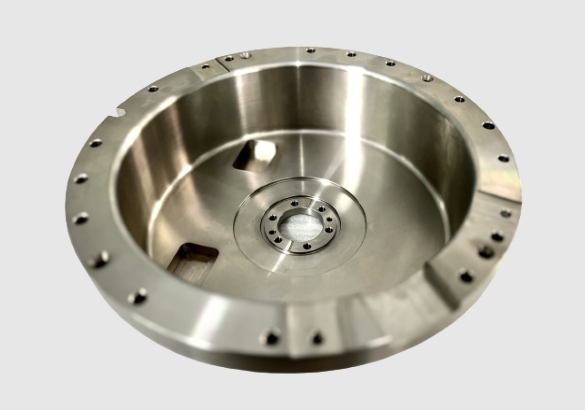

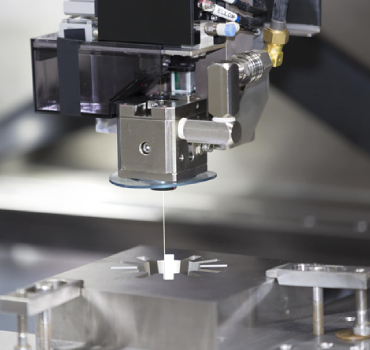

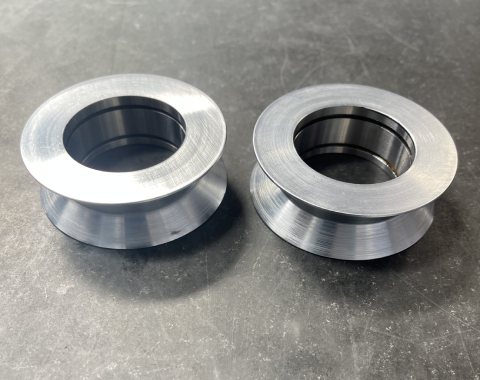

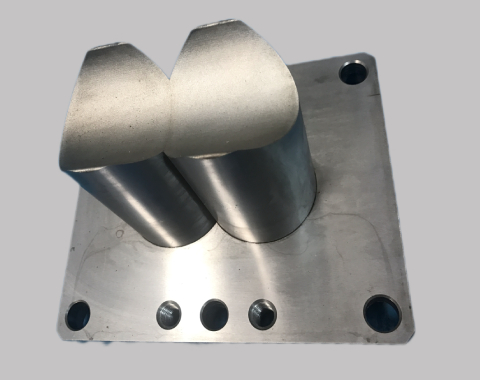

Our commitment to precision machining and investment in cutting-edge technologies has enabled us to achieve an accuracy level of 0.005 millimeters,

earning us a reputation for delivering high-quality products and services.

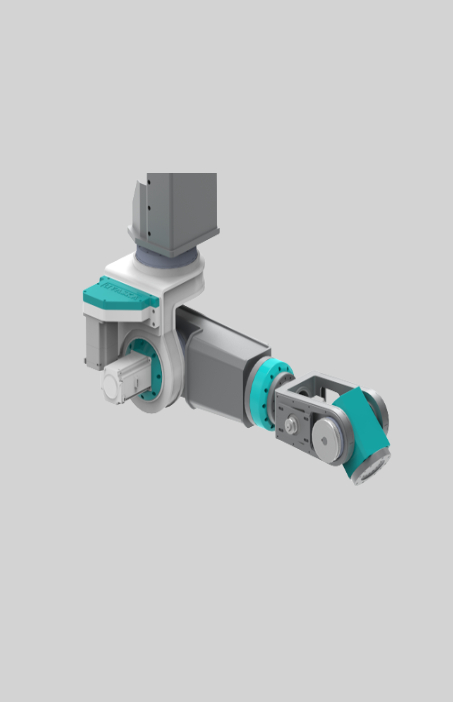

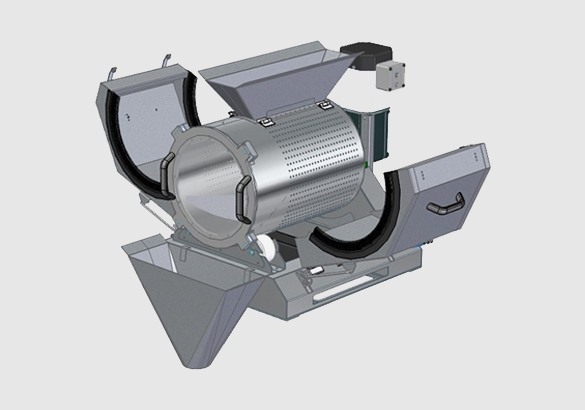

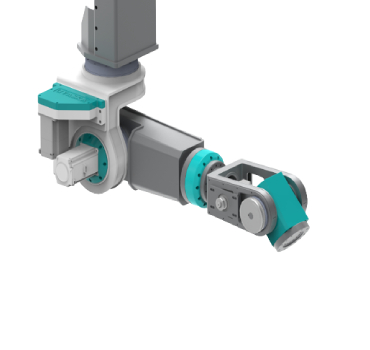

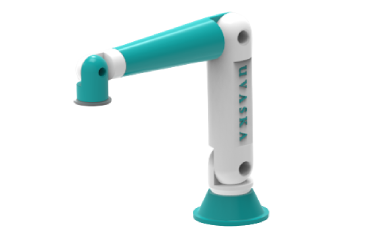

In addition to staying up-to-date with the latest advancements in the industry, UVASKA-ETS has also invested in the research and development of industrial robots

to offer innovative solutions to its customers. We are dedicated to sustainability and follow ISO standards in all aspects of our business.

Our open and innovative approach to customer engagement makes us a reliable and valuable partner for any industrial solution needs.

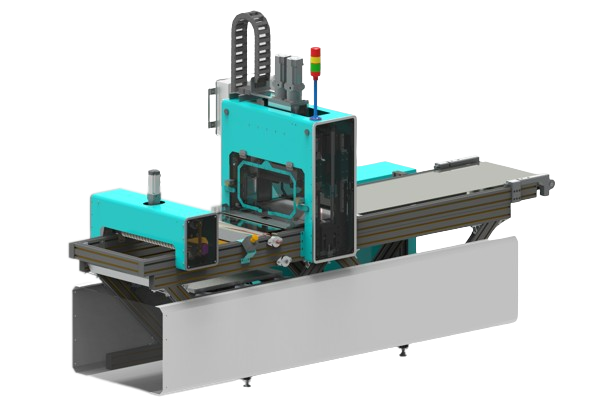

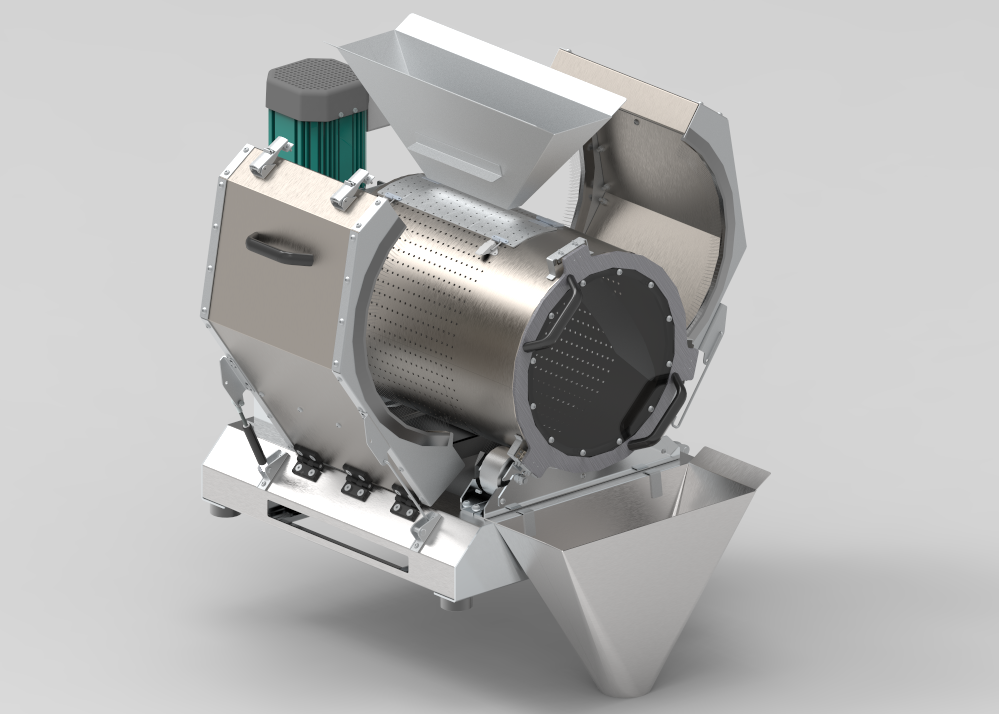

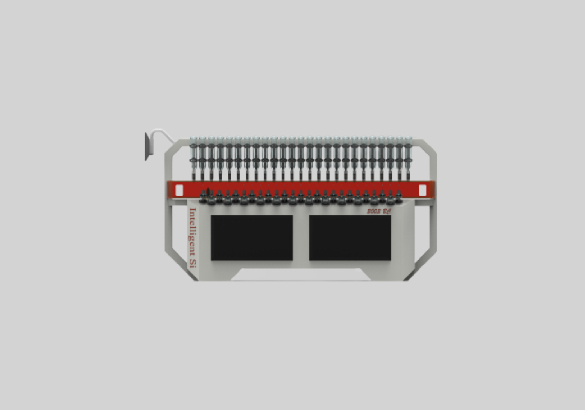

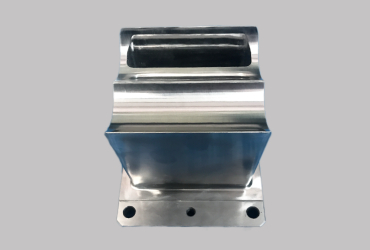

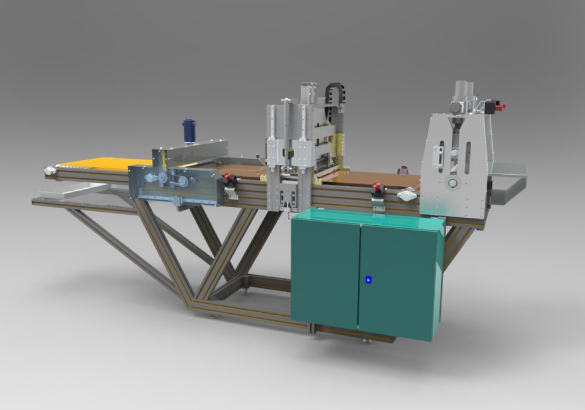

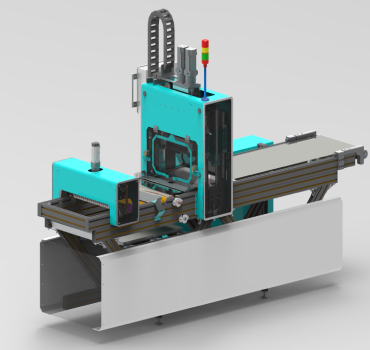

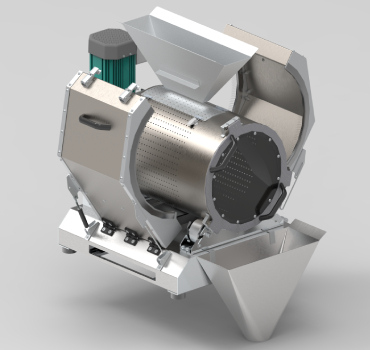

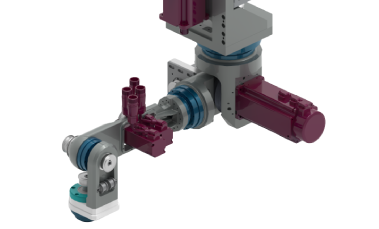

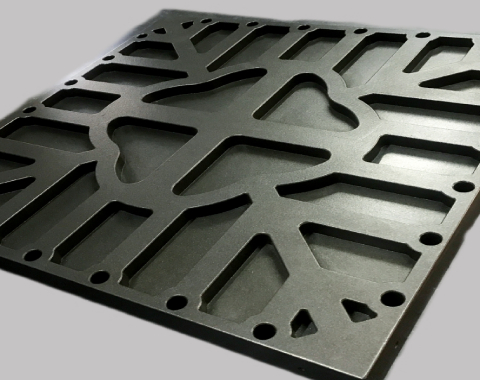

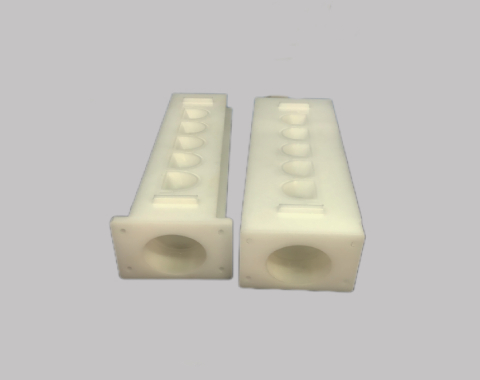

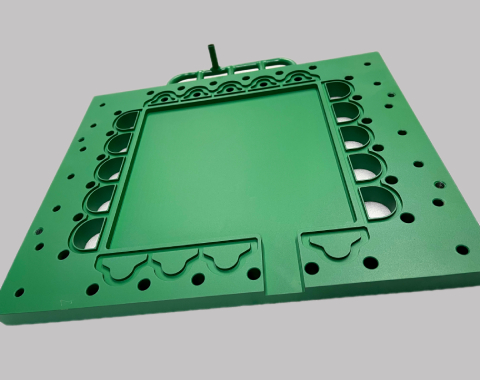

We provide a comprehensive range of services, including manufacturing and assembly, precision components, machined/fabricated items, design and development,

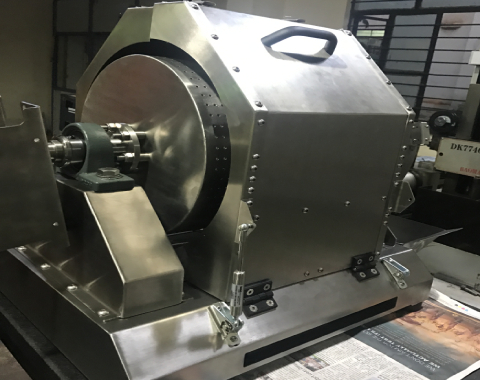

customer purpose machines, industrial and robotic automation and industrial robotics for the transportation, medical, aerospace, infrastructure, green energy,

and Hi-tech industries. We also have the expertise to manufacture custom machines based on our clients' requirements.

01

Vision

Our vision is to revolutionize the manufacturing industry, delivering products and services that enhance lives and drive progress. We believe in the power of innovation and efficiency and are dedicated to continuously pushing the boundaries of what is possible. We strive to create a positive impact on the world, leaving a lasting legacy of excellence and inspiration for generations to come.

02

Mission

Our mission is to empower the world through innovative and sustainable manufacturing solutions. We are dedicated to delivering high-quality products, driven by a commitment to excellence and a passion for continuous improvement. Our team of experts strives to exceed customer expectations and make a positive impact on the communities we serve.

We take pride in our dedication to maintaining a culture of quality in all aspects of our business. UVASKA-ETS has implemented Total Quality Management processes

and strategies to ensure the continuous improvement of our products and services. Our team carefully selects materials and processes to meet strict product

specifications. We conduct inspections at every stage of manufacturing to guarantee that our products meet high-performance standards and minimize waste and rejection.

Only products that have been certified as fully compliant with customer specifications are delivered.

To ensure the best possible performance and quality of our machines, we make a point of keeping them well-maintained on a regular basis.

We also regularly calibrate our testing and measuring instruments to ensure that they are precise and accurate. By taking these steps, we are able to

provide reliable and high-quality products to our customers.

UVASKA-ETS is committed to meeting the needs and goals of our customers with precision and excellence, and we look forward to being your partner for all your

engineering, manufacturing, and automation needs.